The specificity of industrial buildings in their multi functionality. It can be small workshops, warehouses, administrative and technological premises, industrial workshops and laboratories. In each case, their own requirements for the ventilation system.

The design of Ventilation system takes place at the stage of creating the construction project of the entire building and according to clearly defined parameters. Even at the stage of project creation, the functionality of the premises and the tasks to be performed by the ventilation system are determined.

Warehouses. In most cases, the room is equipped with a natural ventilation system. It is the least expensive. Air exchange occurs in a natural way, as through an open window. But for the storage of many foods, fruits, vegetables, medicines, it is necessary to maintain a certain temperature, humidity. In some cases, such as when storing batteries, an explosive gas is released, which must be constantly removed from the room. Such warehouses are equipped with a supply and exhaust ventilation system with air conditioning.

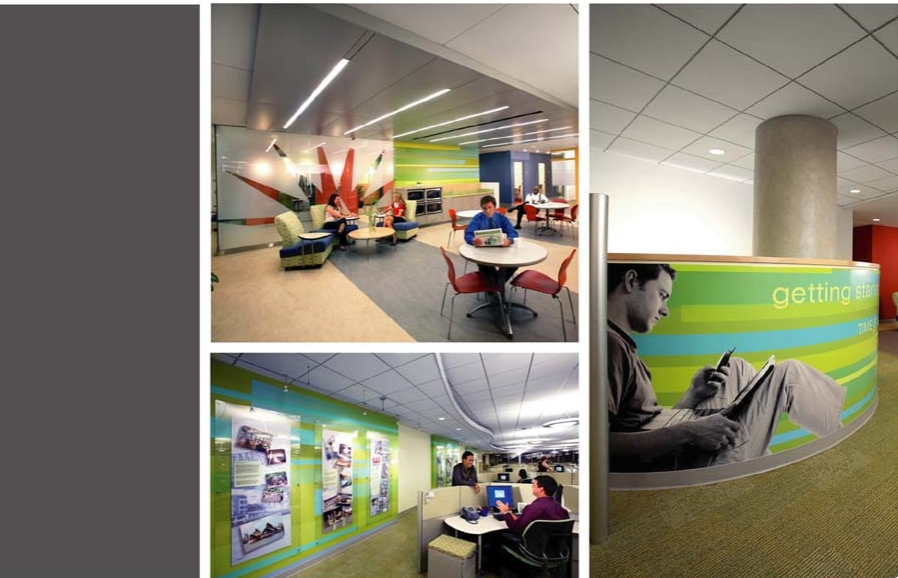

Administrative and technological premises. These include high-tech workshops and rooms with control panels. Modern sophisticated electronic equipment for smooth operation requires maintaining a certain microclimate. The same requirements apply to the air in administrative premises, offices. In these cases, a standard supply and exhaust system with basic air purification filters is used.

Laboratories. Microclimate requirements in laboratories are similar to requirements for administrative buildings. The exception is medical facilities and research when the formation of harmful gases. In these cases, special filters and the possibility of more flexible control of temperature, air flow and humidity are required.

To remove harmful gases and bacteria, to prevent the development of mold, local fume hoods should be provided, which should be linked to the general ventilation system to compensate for the amount of exhaust air.

Workshops. These production facilities are usually small in size and with a minimum number of employees. There is enough installation of supply or exhaust ventilation. If the work of the workshops is associated with the release of harmful gases, dust or other small mechanical impurities, a more powerful exhaust ventilation system and additional air purification filters are installed.

Industrial shops. As a rule, the central ventilation system is used, the main units of which are located on the roof or in a special room, the air enters the shop through an extensive duct network. The air conditioning system is installed only where it is economically justified.

In industrial workshops it is possible to supply the supply and exhaust channels to each workplace. It does not allow gas, dust, which are formed during work, to spread throughout the room.

The main parameters in the calculation of the ventilation system of industrial buildings:

- The size of the room, its geographical location.

- Category of work.

- Type of production.

- Number of employees.

- The duration of stay of employees in the room.

- The location of jobs.

- Total load of each room in the building.

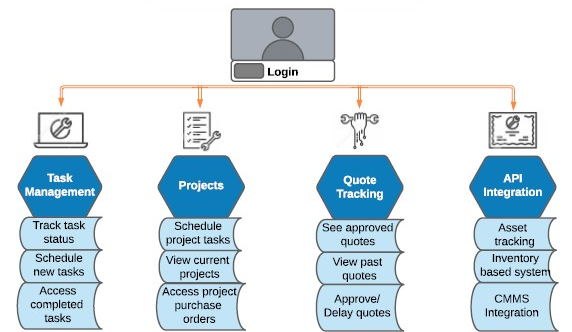

The design of the ventilation systems of industrial buildings is of three types.

Local – installed in small rooms.

Central – used for large rooms, workshops, warehouses. It has a single control center. Central systems can be with or without the possibility of flexible control of air parameters for each room or workplace. Central systems with the possibility of flexible control of air parameters for each room are called VAV systems, with variable air flow.

The ventilation system can be equipped with air conditioning.

The emergency ventilation system works only for air outflow, removal of smoke and gas. Emergency ventilation is activated automatically when necessary.

Core modules

The ventilation system has a modular design. The availability of modules depends on the tasks that are put in front of the ventilation system in each particular case.

Filters for air purification. Virtually any ventilation system is equipped with a cellular or pocket dust filter. Through it passes both outside and recirculated air. Antibacterial, adsorption filters can be installed.

Air heaters. Used ventilation systems for heating the air in the cold season.

Air coolers. For large industrial buildings, water or freon heat exchangers are used as an air cooler.

Humidifier. After cooling, the air drains significantly. To maintain the desired value of humidity using the chamber irrigation or steam humidifier.

Fan for forcing air through ducts.

Sound attenuators. To reduce noise from ventilation can be installed mufflers.

Installation

Installation of the ventilation system occurs during the construction of the building. It is also possible to install a new ventilation system on an old building. This is a more laborious process.

The main stages of installation of the ventilation system:

- Laying of pipelines, air ducts;

- Installation of valves, pressure regulators;

- Installation of system units: fans, coolers, heaters and others;

- System test.

After complete assembly of the ventilation system and the availability of the building, three tests are carried out. They are attended by a representative of the organization that was engaged in assembly and installation, a representative of the general contractor and a representative of technical supervision.